University News

WIU Graduate Students Create Their Own Business

May 10, 2016

MACOMB, IL - - Western Illinois University Engineering Technology Leadership students are getting the chance to run a company before they even graduate.

Students in Professor Kevin Hall's "Planning Techniques for Leaders" (ETL 548) course have created their own business and are churning a profit.

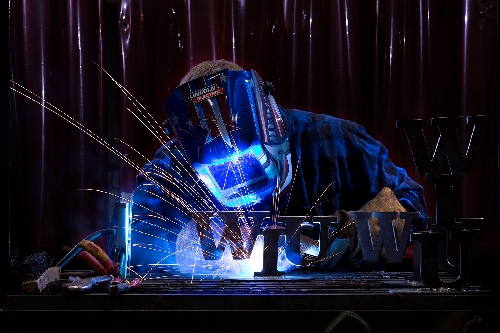

It all began when Hall inherited a plasma cutter from a WIU employee when the employee left Western. Hall chose to utilize the machine in his ET 241 course, which resulted in students welding together WIU signs. Hall decided to consider incorporating those signs into his graduate course, ETL 548, the following semester.

He began the semester by giving the class two options: the typical graduate course format of lecture and research or create a mock business. They chose option two. At that time, little did they know that it would turn into running an actual business for profit.

The students dove right into the project. Hall divided them into four functional teams: human resources, design, production and marketing. The teams run like an actual organization and are responsible for operations that would be in those business departments in a real company. Human resources creates safety manuals and signs, a cross skills matrix, instruction manuals, etc. Marketing met with different areas of the University to get approval for use of the WIU logo and to have someone create a label for the bottom of the statues, as well as to get approval to sell them. Marketing also performs customer analysis, creates surveys and holds focus groups. They bring their results to the design team, who, in turn, is tasked with using software to create prototypes and designs for the product. Production is in charge of efficiently and effectively creating the product that not only sells, but also will make a profit.

"The students create product lines, see how a business runs and get leadership and team building experience. They also learn how to handle roadblocks or any problems that arise. There are a lot of takeaways from this setup," said Hall.

Hall explained how the production team dealt with an efficiency problem they encountered.

"Since we aren't a real company, and we don't have a budget, we have limited tools to work with," he said. "The students created a paint booth, but it was taking a long time to paint, wait for different sides to dry and then rotate and paint again. They created a quick-change paint booth with magnets for speed and efficiency. Since we are producing metal statues, the production team can put a magnet on the bottom and hang the statues upside down and paint all sides at once, then remove it and hang it somewhere else to dry, while being able to move on to the next product to paint."

To make sure each student gets a chance to learn the different team operations, as well as gets a chance to lead each team, Hall set up a rotational system—every two weeks, at least two students rotate out of one group and into another. This system creates its own set of challenges.

"Your team might be making good progress, and then all of a sudden you rotate people and have two new people to catch up. That's the way the industry works though, so they are getting continuous training and learning about talent management, " said Hall.

"Human resources encourages us to cross train our employees," explained Adam Fox, a 2007 engineering technology alumnus and current graduate student from Macomb. "However, when we switch people in groups, this generates a lot of training. For example, I'm in the design group right now. We just got two new people who didn't know how to use the design software, so it's taking valuable time to train new employees on the software."

Fox elaborated on some of the challenges the class/company has faced.

"When we started this semester, the fabrication facility [classroom] was not set up," Fox said. "We took a look at the equipment in the room to decide what we could use, and from there, we tried to optimize the layout as much as we could. Because we don't have money for a budget, we went to the University's surplus storage to gather anything we could use. We brought back a lot of rolling carts and baskets—anything we can use to hold work instructions or customer orders."

However, that wasn't the most difficult challenge. Lata Janga, an engineering technology graduate student from Hyderabad, India, said learning how to operate a new machine (plasma cutter) that none of them had operated before was also a major obstacle to overcome.

"Some of us didn't even have an engineering background or any hands-on experience with something like this," Janga said. "When I started at WIU, I had no idea mechanical work would be part of the curriculum; however, I am so happy that I got to learn important skills that I believe will help me after I graduate.

"It's also hard to maintain quality and productivity when students, our employees, aren't fully trained. I started working in the industry after I got my bachelor's degree, and I have worked in the industry for eight years. I have never had to train employees or keep the whole system flowing," Fox said.

To check progress and learning, as well as to mimic a real company, Hall includes a gemba walk—where the students visit each functional area to understand the work, ask questions and learn—during each class period.

"Each team has about seven minutes to give a report, which includes four things—what they accomplished, what they did not accomplish, why they didn't and what they are going to do to fix that," said Hall. "Everything is condensed down for our company. In an established company, executives or management would spend about 45-60 minutes every week or two gemba walking."

As the professor, Hall uses this information to monitor their progress and as a measurement of learning. He also does unannounced audits to check their procedures and improvement.

"This class is about leadership roles and experience," Hall said. "I need to make sure the students are getting that knowledge and proficiency out of this unique learning environment."

"We are so proud that in such a short time, we were able to stand up what is pretty close to a real-world factory," he added. "The University has been so supportive."

The University Union bookstore agreed to set up a display and sell several product lines. The students are also selling the statues at their "company headquarters," which is located in Knoblauch Hall 127, and the engineering technology office. Prices vary depending on size and product line. Fixed signs, which are sold in the bookstore, range from $5-$15. Custom works range from $20-$50. The profits go directly back to the Engineering Technology department.

Hall said the goal is to sustain this mini-factory, even when the semester ends.

"Our goal is to have this set up and running efficiently, so when a new class comes in, it's an intuitive system," said Hall. "The students seem to really enjoy the class and have fun. We might be able to incorporate some of the hands-on learning into 200 level courses, as well. They can come in and learn the processes to create a product."

Not only are the students making a profit, but they are also getting great experience to add to their résumés and having a good time learning.

"In the real world, you don't get the latitude to make decisions on how teams are set up and how you're going to do quality control systems. I really like that in this class it's up to us to make these decisions because it teaches us so much more about the big picture," Fox said.

"We are very proud that we have started a totally new and original initiative," added Janga. We are so honored to be the first people to get to work on this. It's exciting to be associated with this and to have learned very important skills related to developing and getting a finished product—the whole experience has been amazing for me."

"In my 21 years of teaching, I have not had a more innovative and motivated bunch of students," Hall said.

For more information about purchasing a WIU sign, visit the University Union bookstore, or contact Hall at K-Hall@wiu.edu. For more information about the WIU Department of Engineering Technology, visit wiu.edu/engrtech.

Posted By: Alisha Looney (AA-Looney@wiu.edu)

Office of University Communications & Marketing

Connect with us: