University News

Western Illinois University Faculty and Staff Make Use of 3-D Printer

August 28, 2013

MACOMB, IL - - Western Illinois University faculty and staff added a new tool to their repertoire when WIU received a technology upgrade in the form of a 3-D printer.

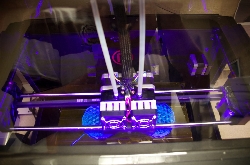

This summer, WIU purchased the 3-D printer in order to offer faculty and staff an opportunity to print 3-D plastic models in place of a two dimensional image on paper. According to Roger Runquist, director for the Center for Innovation in Teaching and Researsch (CITR), where the printer is located, the machine is 15 inches tall, 19 inches wide and 13 inches deep, and it can create 3-D objects up to the size of a small loaf of bread.

The printer is available to WIU's faculty and staff for research and classroom projects. Anyone who wishes to use it will need to provide a usable CAD (computer-aided design) model, which can be created in Google Sketchup, a free program for educators, or any other program capable of creating the type of file needed.

Western's Disability Resource Center (DRC) is currently collaborating with Leslie Melim, geology professor, and Brian Knecht, a senior geology major and DRC tutor, to utilize the 3-D printer to make an oceanography course accessible to a blind student.

"Oceanography and other geology courses are very visual in nature," said Tara Buchannan, DRC director. "Instructors typically use a lot of diagrams and other illustrations to convey geologic information to students. Our goal is to make these visual images accessible to a blind student by printing 3-D images that can be navigated using touch rather than sight."

"The level of detail the machine is able to produce is sometimes surprising," added Runquist. "The software is actually pretty easy to use, as well."

John Cooper, director of jazz studies at WIU, is also experimenting with the printer in his discipline. He created a custom mouthpiece for his trumpet. Cooper said the ability to control minute details about the shape of the elements in an instrument mouthpiece can play a large role in how playable it is. This technology allows for manipulation of any aspect of the mouthpiece in order to customize it for an individual and enhance its playability.

"I am excited about the possibilities of making custom mouthpieces my students can try," Cooper added. "It may help them, at a very low cost, to zero in on tools that can help them be more effective as performing musicians. Once a prototype is finished in plastic, the specifications can be sent to a CNC (computer numerical control) machine where a fairly cheap brass mouthpiece can be fashioned. From there, it can be plated in silver or gold for only the cost of the plating. Students can have a completely custom mouthpiece for probably less than $30 that would normally cost hundreds of dollars to develop."

Cooper added that, "Roger was a great help in understanding the flaws we were getting initially in the results and making adjustments to the file until we got a usable prototype."

For more information on the 3-D printer, contact Runquist at r-runquist@wiu.edu or call (309) 298-2243.

Posted By: Alisha Looney (AA-Looney@wiu.edu)

Office of University Communications & Marketing

Connect with us: